Want useful metrics for your maintenance program?

Get Key Maintenance Metrics

What is an equipment maintenance schedule?

Nearly all equipment and heavy machinery needs some kind of regular maintenance aka an equipment maintenance schedule. This type of maintenance is usually called preventive or planned maintenance (PM).

Sadly, this is an often overlooked aspect of maintenance management and often skipped.

Just think about it…

Preventive maintenance helps reduce the possibility of unexpected failure or repetitive equipment breakdowns. This equipment downtime results in big costs due to lost production, variable product quality and poor customer satisfaction. Therefore, it is critical that we do not delay preventive maintenance or completely drop it!

Preventive maintenance (PM) can be a simple as doing a weekly check, to replacing a machine once it has done some number of run-hours. Every equipment should have a PM schedule.

However, if we have a lot of machinery and equipment it can become very hard to plan for all of them! Trying to use paper charts to plan this maintenance will quickly become rather complicated. We will probably miss some maintenance jobs resulting in many headaches.

Have you ever had this happen to you?

This is where a good maintenance management program aka CMMS software is very useful. Most maintenance programs offer a rich subset of ways to schedule such maintenance work orders. In addition they keep track of our maintenance plan and frequently offer a maintenance calendar that makes it easier to schedule needed maintenance.

Ways to create an equipment maintenance schedule

Basically we want a way to generate maintenance work orders for an equipment based on a preventive maintenance plan. Such an asset maintenance plan would involve regular inspections, repairs, and replacement of machinery and equipment to prevent breakdowns, reduce downtime, and extend the lifespan of the assets. The equipment manufacturer may have recommended the scheduled maintenance tasks in the plan. Or you can put together one based on the typical needs of such equipment. For instance filters to be replaced every three months, lubrication to be done after 300 run-hours and so on.

An important element of such schedules is being able to specify parts and supplies required for each scheduled work order. This allows for better maintenance inventory management and cost control. You can reduce out of stock situations and plan in advance when to buy parts and supplies.

1. Schedule work by date

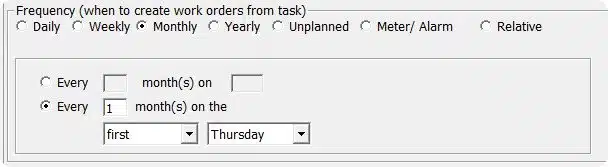

We schedule maintenance work orders every “X” days, weeks or months. So we can have a maintenance task scheduled every 5 days, on every Friday, the second Monday of every third month, every January on the first Wednesday and so on.

Fig 1. Schedule preventive maintenance every month (from FastMaint CMMS)

2. Schedule work by meter reading

There are two different meter types.

In one we schedule maintenance every time a meter reading increases or decreases by a certain amount. For example an oil change when a meter reading increases by 3,000 miles.

The second type is a batch meter. We schedule maintenance after a machine processes “N” units. For example lubricate a bearing every time the equipment produces 500 widgets.

3. Schedule work by equipment alarms

We schedule a maintenance task every time an alarm condition happens. For instance an alarm could be excessive vibration on a machine. We can schedule a preventive maintenance check on the machine when this alarm occurs.

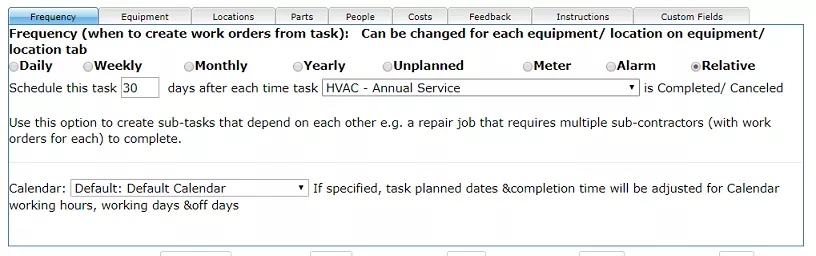

4. Schedule work based on completion of other work

This means we start a new maintenance task when another task is completed. For instance, after we complete a machine repair, we schedule a calibration. Or we schedule a paint job after a dry wall repair and so on. This is very useful for multi-step maintenance. For example, work that needs to be done by different sub-contractors one after another. Once one sub-contractor is done, we schedule the work for the next sub-contractor and so on.

Fig 2. Schedule maintenance based on another maintenance work order (from FastMaint CMMS)

For a more detailed review of the different options and how they can be used in the FastMaint CMMS software see “How To Schedule Preventive Maintenance Work Orders“.

You should also have a way to receive and process maintenance work requests. In addition to addressing immediate issues, maintenance work requests also play a crucial role in preventive maintenance. By identifying and addressing small maintenance needs before they develop into more significant problems, the facility can avoid costly downtime and repairs.

How this equipment maintenance schedule helps us

Once we setup our maintenance management program we will start to see the amount of reactive maintenance due to equipment breakdowns decrease. Equipment downtime should start to decrease. Time spent on preventive or planned maintenance will increase. We will see cost savings in the maintenance budget due to less emergency maintenance.

In addition maintenance spare parts management should improve. We can better avoid stock outs and delays in repairs, which can lead to decreased customer satisfaction and revenue loss.

Moreover, since it facilitates timely maintenance and repairs, this can extend the lifespan of equipment and reduce the need for costly replacements.

Plus there will be benefits in terms of better equipment availability, meeting production goals and customer satisfaction!

See “Calculating CMMS Return On Investment” for more information. It gives one an example to calculate the benefits and return on investment (ROI) of maintenance management software.

Don’t forget to check equipment maintenance reports

You should also regularly check maintenance plan health and review equipment maintenance logs for unusual events that may require changing maintenance scheduling options.

Effective equipment maintenance reporting helps organizations to identify potential equipment problems before they escalate and become major issues that could result in significant losses. It enables organizations to plan and schedule maintenance activities in advance, ensuring that all necessary maintenance is carried out on time, and equipment remains in good condition. Additionally, maintenance reporting helps organizations to track the lifespan of their equipment and plan for equipment replacement when necessary.

Bottom line – good maintenance planning makes all the difference.

Maintenance scheduling program recommendations

To make an effective maintenance plan we will need good equipment maintenance scheduling software. This is especially true when there is a lot of equipment!

Don’t have a good maintenance software program? You can get a web demo or download a trial of FastMaint CMMS software. Even with the online demo you should be able to setup a simple equipment maintenance schedule for your maintenance jobs very fast. It will make it much easier to keep on track with preventive maintenance plans for your equipment and facilities. See this food manufacturing plant maintenance case study for how FastMaint has helped them.

Free FastMaint CMMS TrialWant useful metrics for your maintenance program?

Get Key Maintenance Metrics