Essential Maintenance Metrics Every Planner Needs to Know

Get Free Guide

Some maintenance jobs can be costing more than you thought!

Maintenance managers often look at equipment maintenance software reports by equipment to find equipment that is getting expensive to maintain.

But that’s just part of the story…

There are other ways to to slice our data and look for ways to reduce costs and improve effectiveness.

Looking for maintenance costs on a different “dimension”

For instance consider the costs of different maintenance tasks or jobs. This is especially relevant when we have lots of very similar equipment. We may have several pumps of the same model, several similar HVAC units and so on.

In such cases all these equipment have very similar maintenance cycles. We may have done a good job and found and fixed all the bad apples in the bunch. However, an underlying issue may be that this model of equipment really requires far too much maintenance – preventive or corrective.

So it may be time to do a wholesale replacement of this type of equipment with a new model or something else. Doing such a full replacement can be very expensive. It is often disruptive.

This means we really need to have an idea of what the old equipment is costing us before we jump on doing such a replacement.

Equipment maintenance software reports with maintenance task data

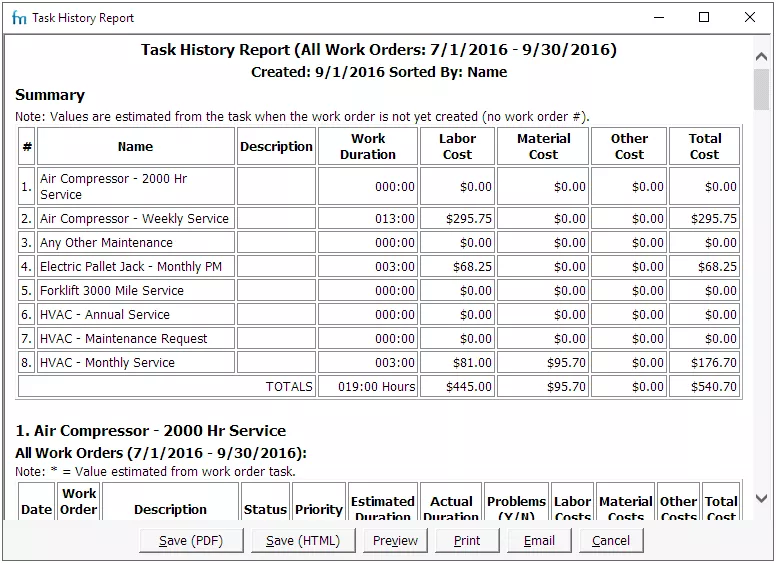

One of the reports we can use is a task history report. This allows us to compare costs and work order duration by different maintenance tasks. Say we have maintenance tasks specific to a class of equipment. For example it could be HVAC units we use in our facility. With the task history report we have a way of identifying how much these units are costing in time and money.

We want to make sure that most of these costs are not due to a few bad apples. This means just a few equipment that keeps failing is responsible for most of the work. This is where the equipment history report for the same period can be useful. We can see if the higher costs are due to just some equipment. Or it may be that equipment model is expensive to maintain!

Importance of the maintenance task history report

The task history report allows us to compare different types of task costs. We can compare labor costs, material (parts & supplies) costs and so on. We may find that some task maintenance costs are rather high because of very expensive spare parts. Alternative part suppliers could help reduce such costs.

If labor costs are very high we can dig in to find the reason. Maybe we are using expensive outside subcontractors with specialist skills to complete the work. We may be able to reduce costs by getting training and building in-house skills.

For instance look at the screenshot below of a task history report from our FastMaint CMMS equipment maintenance software. We may wish to dig into why Air Compressor – Weekly Service has a much higher duration and cost than other tasks. The reason could be rather benign.

We may have many air compressors. So lots of work orders are created for the weekly service on each of them. Or we may find that they are getting costly to maintain. It may be time to change to a newer model of air compressor.

We see that using a combination of an equipment history report with a task history report allows us to aggregate data in two different ways. This can uncover issues and trends not just with some equipment. Possibly a whole class of equipment needs replacement or changes in the maintenance program.

Other useful maintenance metrics

Using data from our equipment maintenance software we can get several other useful metrics that can be helpful to improve our maintenance program. For more information get our free guide “Key Maintenance Management Metrics for Maintenance Planners“.

Download Key Maintenance MetricsEssential Maintenance Metrics Every Planner Needs to Know

Get Free Guide