Want useful metrics for your maintenance program?

Get Key Maintenance Metrics

Why preventive maintenance is a problem

Working with operations to schedule preventive maintenance for vital equipment & facilities can be a challenge for maintenance managers. Preventive maintenance scheduling is low on the totem pole!

Don’t look at me like that!

Shutting down equipment for recommended maintenance can be hard to justify when there are production deadlines and possible penalties for missed delivery dates.

This often means that breakdown maintenance is a priority (see “7 Breakdown Maintenance Planning Tips” for some useful tips). After all, equipment needs to be up and running again!

Have you ever had this happen to you…?

On the other hand, regular preventive maintenance is essential to keep equipment running smoothly and within operational limits.

Sadly doing such maintenance often falls low on the list. We frequently find maintenance departments are overextended dealing with breakdowns. In addition, shutting down critical machinery will cause production backlogs or other operational issues. Hence, it hard to convince operations staff to do a shut down just for planned maintenance.

So what can you do?

Plan preventive maintenance for shutdown periods

Different equipment will have different maintenance cycles. Ideally we want all of the different maintenance tasks to occur as close together as possible. Therefore this will reduce equipment downtime while maintenance is being done.

Many organizations plan a maintenance shutdown period. This is usually during the holidays. During this shutdown, major maintenance work can be completed with minimal impact to operations. However, many equipment will be on different preventive maintenance cycles. This can make it difficult to ensure that all needed maintenance falls within the narrow window of the shutdown period.

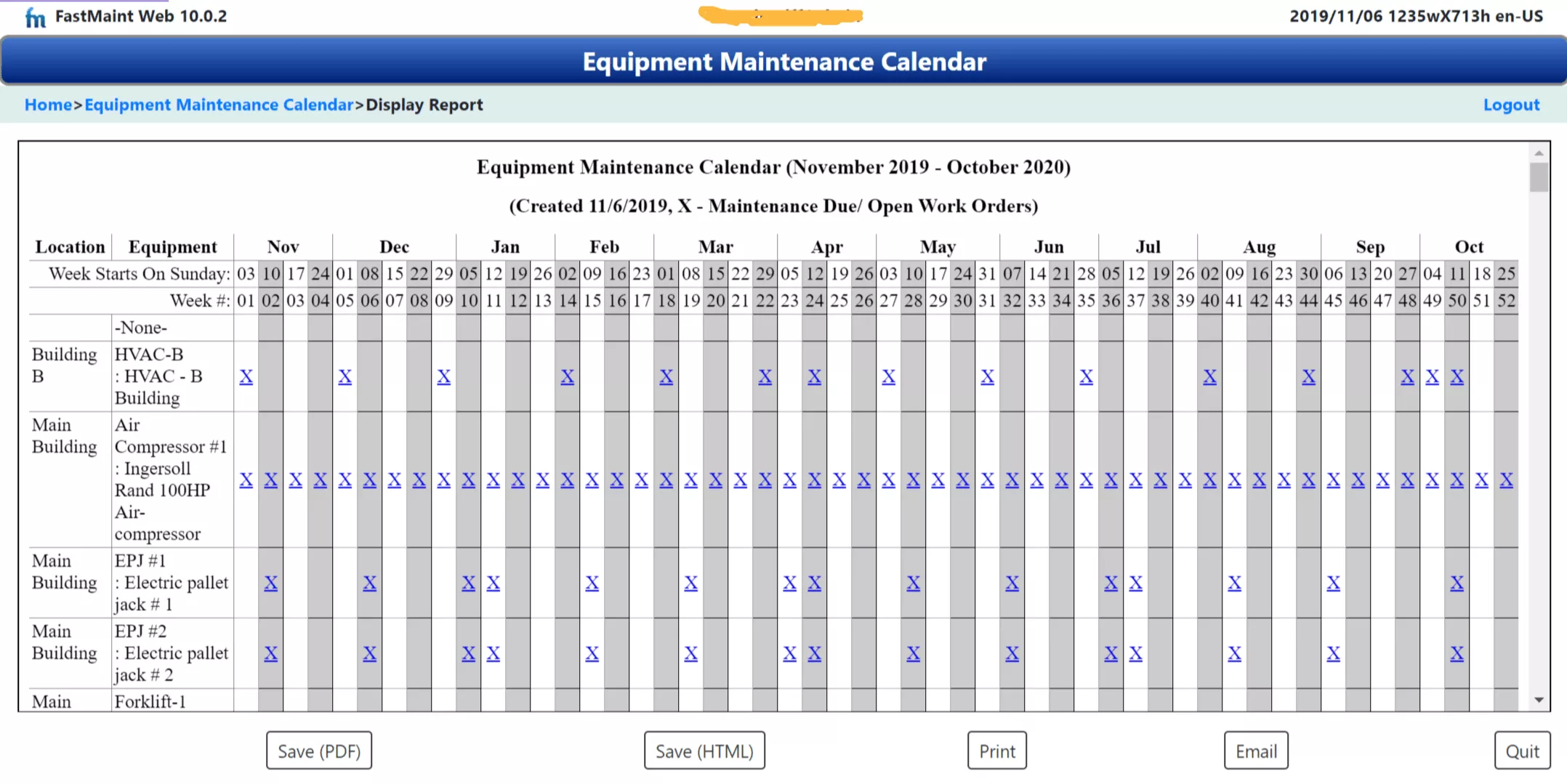

Use an equipment maintenance calendar

Many maintenance software programs allow you to create an equipment maintenance calendar. This will be a report or a display on the screen. Use this calendar to see several months ahead. You can find what preventive maintenance is due for each equipment. After that, you can make changes to the schedule settings for each preventive maintenance task. Get as many maintenance jobs as possible to fall within the shutdown period.

Fig 1. Equipment maintenance calendar report (from FastMaint CMMS)

When you have a lot of equipment this scheduling can become complicated. There are several things you can use to make it easier. For example, use equipment hierarchies, combine work orders, outsource work and more. You can learn more about this from “7 Tips To Plan Equipment Preventive Maintenance“.

Need CMMS software to create your maintenance calendar?

Get a free 30-day trial of FastMaint CMMS software. You can use the Cloud version or download the software. You should be able to start using it in a few minutes. Import in your equipment from comma delimited files or spreadsheets. Set up your maintenance jobs. After that try out the Equipment Maintenance Calendar report.

See how useful it can be for your preventive maintenance scheduling!

Free FastMaint CMMS TrialAdditional Reading

- “Fine Tuning Your Preventive Maintenance Schedule” from Plant Engineering magazine.

- “Five Tips For Better Preventative Maintenance With CMMS” from Plant Engineering magazine.

- “The Importance of Preventive Maintenance” a C-Suite Advisory from CEO World magazine.

Want useful metrics for your maintenance program?

Get Key Maintenance Metrics