Some customers

Industrial Machinery & Equipment Management With FastMaint CMMS

- Easy to use equipment maintenance software. Fast to setup. Intuitive screens with extensive help

- Import equipment, product line information, spares & supplies for faster setup

- Schedule breakdown & preventive work. Identify missed work

- Receive work requests from machine operators & schedule repairs

- Manage equipment, facilities, spare parts, purchases and more

- Used by big & small industrial and manufacturing companies

- Cloud CMMS (monthly fee) OR Download on your computer(s) (one time fee)

(Download or Cloud CMMS)

Equipment Maintenance Software Features

Benefits at a glance

Manage equipment breakdowns & quickly create PM plans for machinery, heavy equipment & more. Reduce critical equipment breakdowns due to missed work. Utilize calendars to get work scheduled during shutdown periods to improve equipment availability.

FastMaint is CMMS software suited for manufacturing and other industrial operations such as refining, process industries, mineral extraction, mining and more.

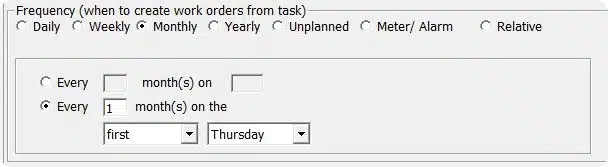

Schedule work with many options

Offers a single easy to use interface to schedule different types of jobs.

For example you can create an unplanned task library & schedule tasks from this library when an equipment breaks down.

Similarly create a library of PM jobs & schedule preventive or planned work for different equipment & machinery. Schedule work on equipment by time (say every three months) or when an alarm is reported, by change in meter readings on the equipment (say after every 800 units produced), another task is completed and so on.

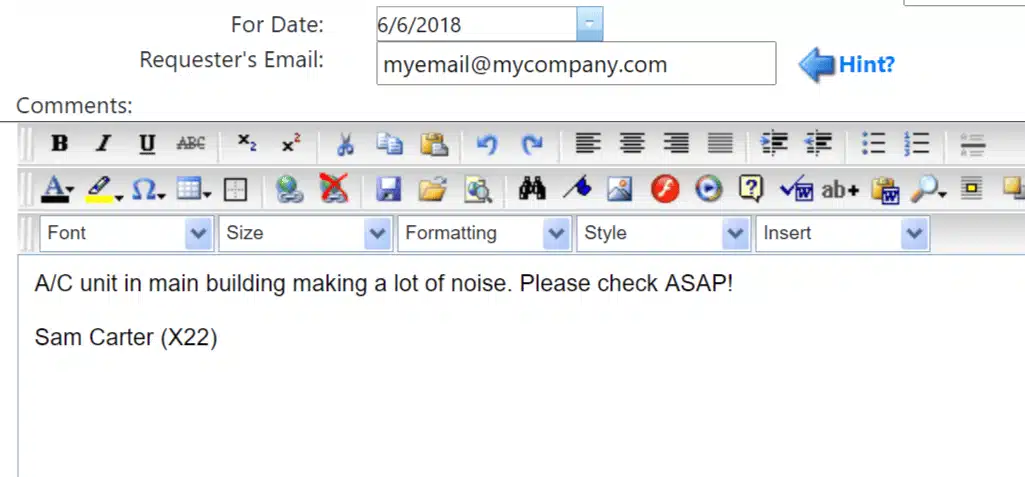

Handling maintenance work requests

Work requests from operators

You can receive work requests from machine operators or other departments. So you can keep track of such requests and make sure none are missed!

They can even submit requests for work by email. So requesters do not need to setup anything or have access to the system. Automatic updates on request status can be sent by email to requesters. In addition, you can also email them for additional information.

Managers can review these requests, create work orders from them or cancel them.

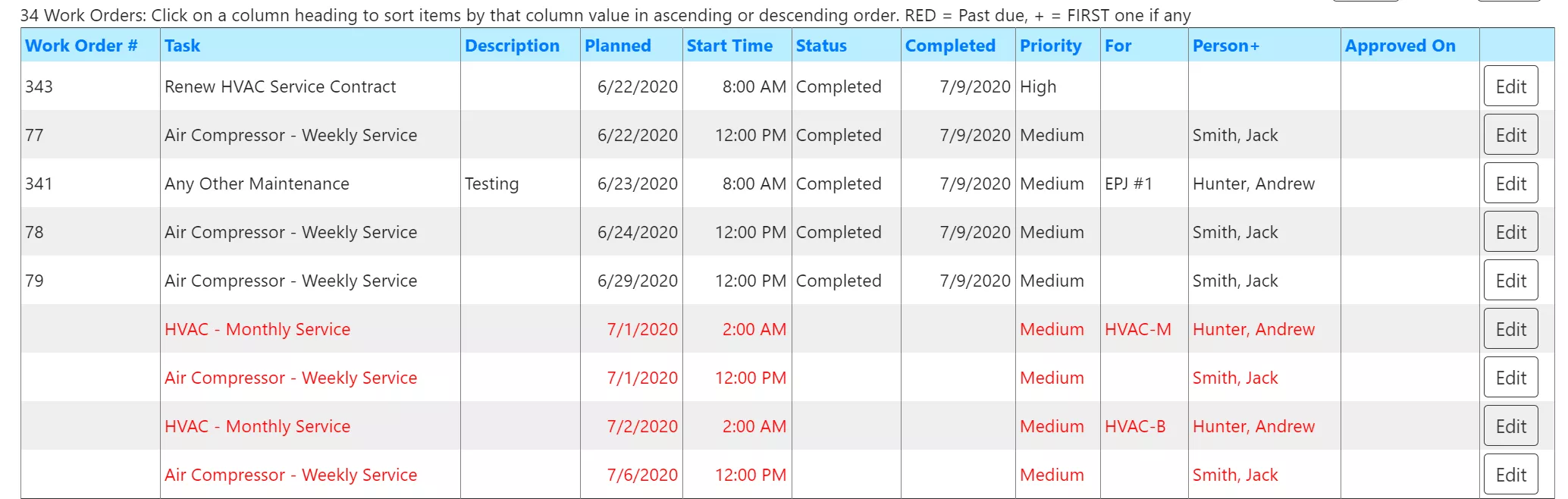

List of maintenance work orders showing current state

Tracking with work orders

Create work orders from work requests and breakdown reports. In addition have work orders automatically scheduled for planned work based on task settings. Then send these work orders to maintenance technicians or outside sub-contractors to complete. You can print the work orders or email them as well as send reminders when they are past due. Reduce work completion errors by printing pictures and detailed instructions on work orders.

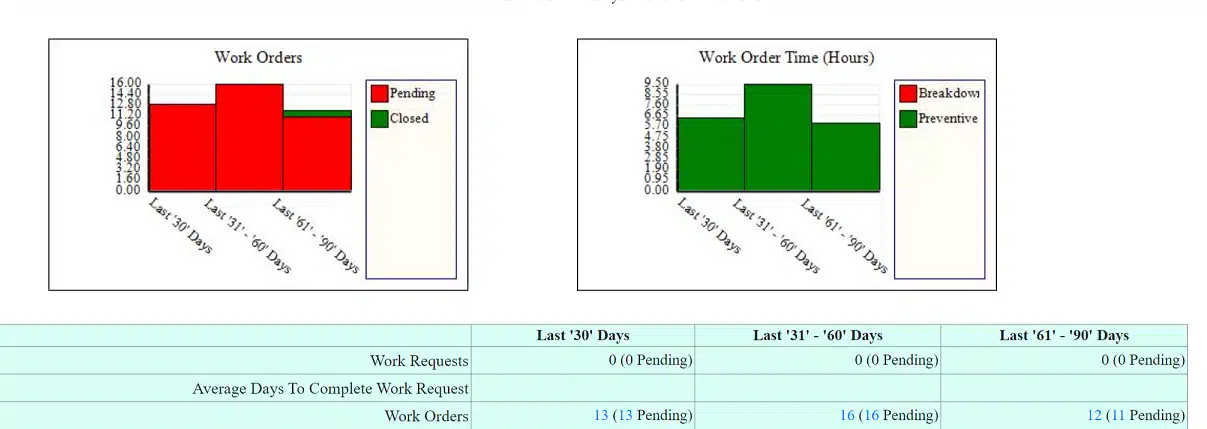

Data analysis & reports

You have access to a variety of reports that can be emailed or printed. Use the reports to get an idea of equipment downtime, spares usage, job costs and so on. For example, use the one-page Statistics report to get an idea of your current situation at a glance.

Customize reports to your needs. You can with the help of the WYSIWYG Report Editor create your own reports. For instance add company logos, custom fields, graphs and so on.

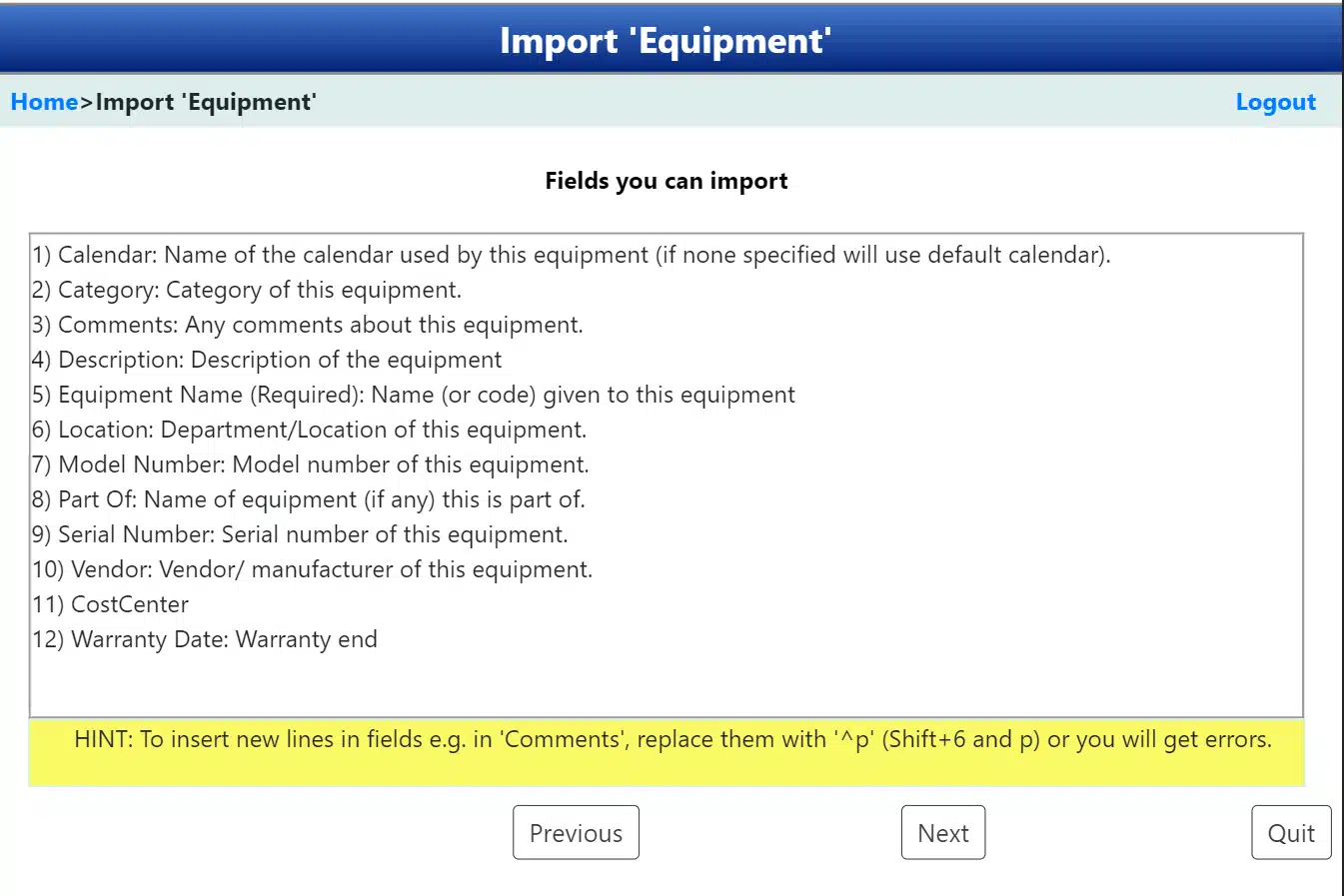

Import data from Excel files for fast setup

Do you have a lot of data in an Excel files or comma delimited files? You can import much of this into the system for faster setup. For example you can import spare parts, task instructions, equipment and so on. As a result, you will get started with FastMaint a lot faster!

In addition, you can use the helpful step-by-step wizard in the Import function to guide you to map your data to the correct fields. If you made any errors, just run the import again to update the data.

Plus you can also export data to an Excel file. For example you can export work orders, spare parts, equipment and more.

Equipment Maintenance Software Used For

Equipment Maintenance Software Tips

From Our Blog

Maintenance management covers a wide area since regular maintenance is required for a variety of assets. A maintenance software program is not only useful in locations with a lot of machines (e.g. manufacturing plants, mining operations, etc.). In addition it is useful where you have a lot of facilities needing maintenance (hotel, resorts, restaurants) as well as those with other equipment (e.g. utilities, vehicle fleets, farm equipment). Does it make sense to look for specialized software based on your industry?

read more

As an operations manager or maintenance manager you will regularly look for problem equipment. These cause frequent shutdowns or incur big maintenance costs. When you have hundreds of equipment it can be hard to do.

Whatever the situation, operations managers and maintenance managers need to regularly identify problem equipment. These bad boys are the ones that cause frequent shutdowns or incur big costs!

read more

Preventive maintenance is a critical function of a maintenance department. The equipment and machines used for production are a manufacturing or industrial operation’s lifeblood. Equipment shutdowns means products not being made or delivered to customers.

Have you ever had this happen to you?

read more

Maintenance request software may seem like a rather specialized requirement! However, if one is responsible for managing maintenance at a large facility or industrial plant we will be handling a lot of requests for maintenance work.

Most requests will be for emergency or breakdown maintenance. Often the requester wants an immediate fix!

But that’s just part of the story…

read more

Do you have a lot of equipment to maintain? Is reactive maintenance aka breakdown maintenance dominating your day? 🙁 Want to create a good preventive maintenance plan to reduce equipment breakdowns and complaints from users and management?

When you have to manage maintenance on many equipment you really must use a maintenance management program aka CMMS software to create your equipment maintenance plan. There may be dependencies between equipment that makes it hard to plan for.

For example it works better to plan maintenance on all equipment in the same assembly line at the same time rather than shutting down multiple lines to do maintenance on one or two equipment in each line.

read more

Nearly all equipment and heavy machinery needs some kind of regular maintenance aka an equipment maintenance schedule. This type of maintenance is usually called preventive or planned maintenance (PM).

Sadly, this is an often overlooked aspect of maintenance management and often skipped.

Just think about it…

read more