Essential Maintenance Metrics Every Planner Needs to Know

Get Free Guide

Public utility maintenance is a critical function

Public utilities cover a wide range of services from power generation & distribution, water supply, gas supply, waste water treatment and more. They provide essential services in a specific geographic area and have unique challenges. Most are heavily regulated and are required to provide uninterrupted services with few or no complications.

Public utilities cover a wide range of services from power generation & distribution, water supply, gas supply, waste water treatment and more. They provide essential services in a specific geographic area and have unique challenges. Most are heavily regulated and are required to provide uninterrupted services with few or no complications.

These demands pose unique challenges to public utility operators. Failure to deliver service produces hundreds if not thousands of irate customers. Pricing changes for services are regulated and need to go through formal approval processes so profit margins are usually slim. Infrastructure costs are very high and very expensive to replace and maintain.

This means that equipment and facility maintenance is a very critical function. Equipment failure leads to inability to provide service or in the worst case hazardous conditions. Of example a waste water spill, a gas line leaks, a retention pond fails and so on. Equipment and facility replacement is very expensive. Good maintenance helps them have a long working life and reduces replacement costs. An effective maintenance management program requires the right tools to be effective and CMMS software (maintenance management software program) is one of them.

Ways Utility Maintenance Managers Can Use CMMS Software Tools

1. Schedule preventive maintenance & calibration activities

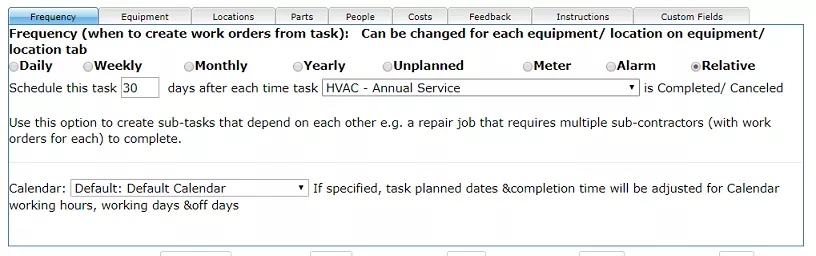

With a variety of different equipment each with its own preventive maintenance tasks and calibration tasks there are quite a few maintenance tasks to schedule and keep track over the year. The utility maintenance manager/ planner will find it easier schedule them with maintenance software. In this example from FastMaint CMMS you can schedule maintenance jobs daily, weekly, monthly, yearly, based on a meter reading or alarm or completion of another task.

2. Identify problem equipment that needs to be replaced or overhauled

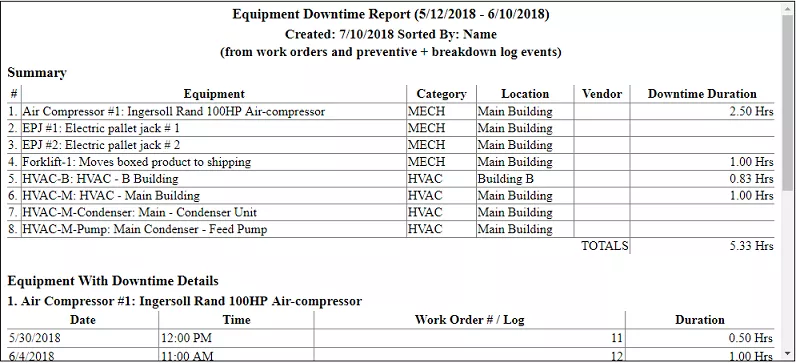

Equipment can be very expensive to replace. However, you will need to replace them or completely overhaul them at some point! A good maintenance software program offers a variety of reports. FastMaint CMMS has an equipment history report can be used to review maintenance costs, maintenance work duration and recorded problems over time. With this information it is possible to identify equipment/ facilities that are causing a majority of maintenance issues and their costs. This makes it easier to justify doing a replacement or overhaul. For example the equipment downtime report (from FastMaint CMMS) can be used to identify equipment which is out of service much of the time.

3. Identify missed or delayed maintenance that can result in equipment breakdown

With so many maintenance work orders to do, it is quite common for some to fall by the wayside. It may get bumped off the list because of a more urgent job. Or there was not enough time to complete it. Maybe spare parts were not available. Or the equipment has problems that require troubleshooting from an expert and so on. Sometimes the most mundane of missed tasks results in a big problems later. Like not checking a cooling water intake filter for debris results in an entire plant/ generator shut down because the cooling water intake gets blocked. With reports provided by maintenance software it is easier to identify such missed or delayed or incomplete maintenance work.

4. Work request management for maintenance requests

External users and others such as equipment operators need a way to report problems or request maintenance. This is used to generate maintenance work orders that are tracked. The work request submitter can also have a way to check the status of the request rather than having to call maintenance staff for updates.

5. Integrated asset management

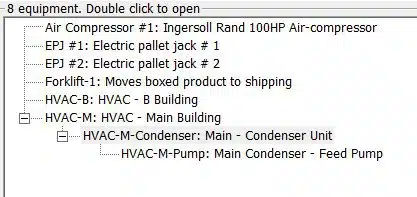

Since you will be entering information on all your facilities and equipment you now have a database of all equipment and facilities and their relation to each other. In FastMaint CMMS you can create an equipment and sub-equipment hierarchy like below. Say a sub-equipment breaks down or needs to go out of service. You can easily identify other equipment that are affected. You can do roll-up reports of all maintenance work done on an equipment and its sub-equipment or all equipment at a specific facility/ location.

6. Reporting that is useful for compliance purposes

You may need to provide regular reports for auditing or regulatory purposes. In the worst case for an investigation after an incident. Use the maintenance software reports to show what maintenance work orders were done, if anything was missed, if any problems were reported and so on.

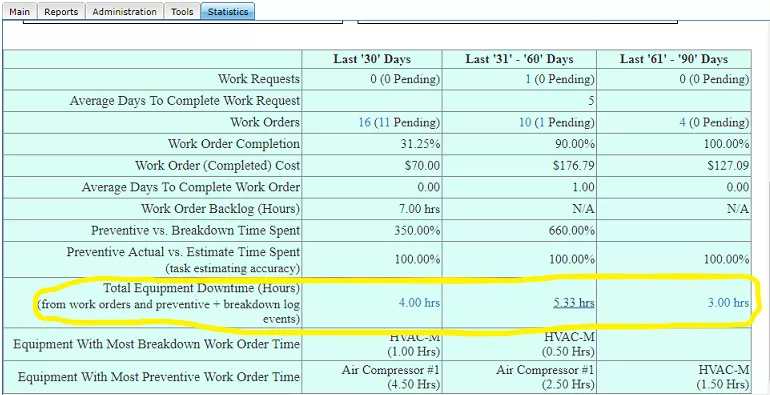

In addition keeping track of maintenance metrics like below (example from FastMaint CMMS) will help identify problem areas in your maintenance program.

7. Spare parts & supplies management

Maintenance software typically come with spare & supplies management. Generally it will not be a full inventory control system. However, you can track consumption of spare and supplies, the costs involved, the equipment it is used for, vendors and so on. When planning or generating work orders it can help you ensure that you have enough spares on hand to complete the job. You can re-order in advance and avoid delayed maintenance. Being able to identify good vendors for spare and supplies ensures that you have good quality spares. Poor quality parts can lead to problems completing maintenance or even worse result in equipment failures.

Maintenance Software Selection Guide

This free CMMS Software Selection Guide will help you identify the features you need from your maintenance software. With hundreds of different products available it can be quite difficult to identify which ones will meet the needs of your public utility. The guide offers tips and questions you should ask to find the right maintenance software program for you.

Free CMMS Software Selection GuideAdditional Resources:

- Equipment/ Machine Downtime Tracking Analysis Tips

- Maintenance Backlog Management For Equipment & Facilities

- Six Ways CMMS/ Maintenance Software Can Improve Vendor Management

Essential Maintenance Metrics Every Planner Needs to Know

Get Free Guide