Essential Maintenance Metrics Every Planner Needs to Know

Get Free Guide

Planning preventive maintenance can be a challenge!

It is important to have an idea of equipment preventive maintenance due for the coming months. We do not want to schedule be too much work in some weeks and too little work during other weeks. However, keeping some low periods can be good for maintenance staff to take time off or go for training.

Yet, if we have a lot of equipment, it can be hard to get an idea of preventive maintenance that is due for the different equipment.

Have you ever had this happen to you?

Preventive Maintenance Scheduling Options

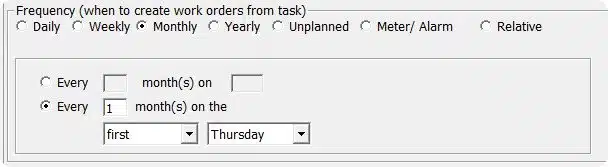

For instance, FastMaint CMMS offers these common preventive maintenance scheduling options. Taken in different combinations they provide a rich subset of ways to plan scheduled maintenance for equipment & machinery over the coming weeks, months and years.

1. Schedule by dates:

This is the most common way to schedule preventive maintenance. You can set how often the work should be done—for example, every Wednesday, every 45 days, or every 6 months.

2. Schedule by equipment use/ meter readings:

We schedule preventive maintenance based on how much the machine is used. For example, a vehicle might get an oil change every 3,000 miles, or a machine might get serviced after producing 1,000 widgets.

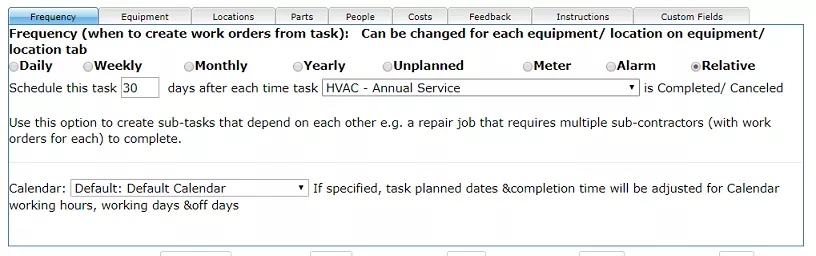

3. Schedule based on completion of other work:

This means a maintenance task is scheduled a certain number of days after another task is completed. It’s useful when work orders need to be linked—for example, if a job involves two tasks handled by different subcontractors.

4. Schedule on an alarm condition:

This lets us set an external condition—like an alarm—that triggers preventive maintenance. For example, if a machine overheats, it may mean all bearings need lubrication. It can also include alarms or maintenance requests triggered by condition monitoring or predictive maintenance systems, which may be separate from the main maintenance software.

What scheduling options to choose & setup steps

For more details as well as upsides & downsides of these scheduling options see “How To Schedule Preventive Maintenance Work Orders“.

Another challenge especially if you are trying to setup preventive maintenance for the first time is what to deal with first. Some useful tips & setup steps are provided in the FastMaint support guide “How to manage preventive maintenance“.

Understanding Your Equipment Maintenance Plan & Making It Work

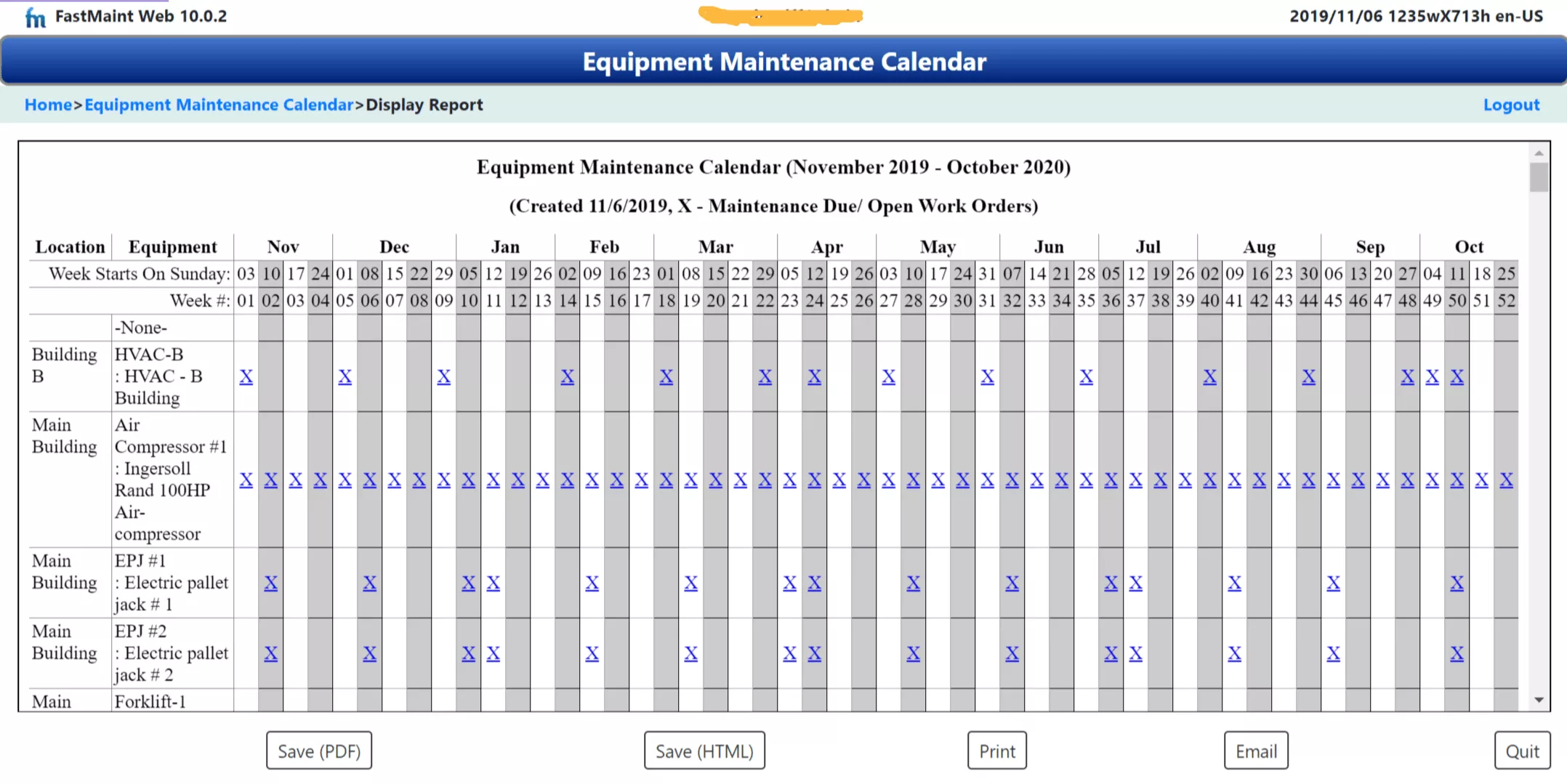

This is where reports from your CMMS software (maintenance management software) can be quite helpful. Look for a report like Equipment Maintenance Calendar or Maintenance Calendar. This report should give you an idea of preventative maintenance due in the coming months week by week.

This is important since you can make changes in scheduling options in your maintenance software to try and get maintenance work for different equipment scheduled at the best time. For instance, get most maintenance scheduled during a plant shutdown period, avoid scheduling during peak production periods and so on.

Equipment Preventive Maintenance Scheduling Tips

1. Plan for unplanned maintenance!

Equipment breakdowns or other issues will need unplanned or corrective maintenance. This means that maintenance staff with required skills must be available even during weeks that not much maintenance is being planned. Having a look at prior year breakdown work orders can give you an idea of the possible work load. But remember that it probably is not accurate since equipment breakdown is quite unpredictable!

2. Maintenance calendars adjustments

You will plan to retire some equipment later during the year. Or you will install new equipment. This will impact the maintenance calendar. You can drop some maintenance tasks after some date while new maintenance tasks may need to be done after other dates.

3. Watch out for work overload

Check carefully and make sure that planned workloads are not unreasonable and you have the staff to do them. If you are overloaded in some weeks change your maintenance task schedules. A work overload will also impact your ability to handle equipment breakdowns during those weeks.

4. Review plans with other departments

Discuss with operations staff if it is acceptable to remove some equipment from service at certain times. For example at a manufacturing plant you would discuss these plans with production management. At a hotel or resort facility you will want to discuss with management for housekeeping, front desk, sales and so on.

You may find it is a busy period and the worst time to do any planned maintenance! Change settings on maintenance task schedules to ensure that planned maintenance dates are adjusted to accommodate such needs.

5. Check demand for spare parts and maintenance supplies

It is also be a good time to get an idea of expected maintenance spare parts demands over the coming months. This will help you order items early from suppliers. In addition having an idea of quantities needed may allow you to get quantity discounts.

For example in FastMaint CMMS, the work order reports have an option to calculate parts usage and availability for future periods. This is useful to get an idea of spare parts & supplies needed and when you will need them.

See “6 Ways CMMS/ Maintenance Software Can Improve Vendor Management” and “3 Ways To Improve Maintenance Spare Parts Management” for some additional spare parts management tips.

Also see at “7 Tips To Plan Equipment Preventive Maintenance” for how to setup your equipment and plan maintenance.

Looking for A Way To Create A Maintenance Calendar?

Get a 30-day trial of FastMaint CMMS. See why it is a good maintenance scheduling software program! Use the import feature to load in your equipment and maintenance tasks. Setup the preventive maintenance plan. You can then use the Maintenance Calendar Report in FastMaint to get an idea of the preventive maintenance due in the coming months.

Free FastMaint CMMS TrialEssential Maintenance Metrics Every Planner Needs to Know

Get Free Guide