Essential Maintenance Metrics Every Planner Needs to Know

Get Free Guide

Why Equipment Downtime Tracking Is Better Than Tracking Equipment Availability

We always want to measure total equipment downtime. Equipment availability especially when expressed as a percent can mislead.

For instance say the equipment downtime doubles from hundred hours to two hundred hours. However, if you have a lot of equipment, you will see just a small percent drop in equipment availability. No warning bells get triggered!

Just think about it…

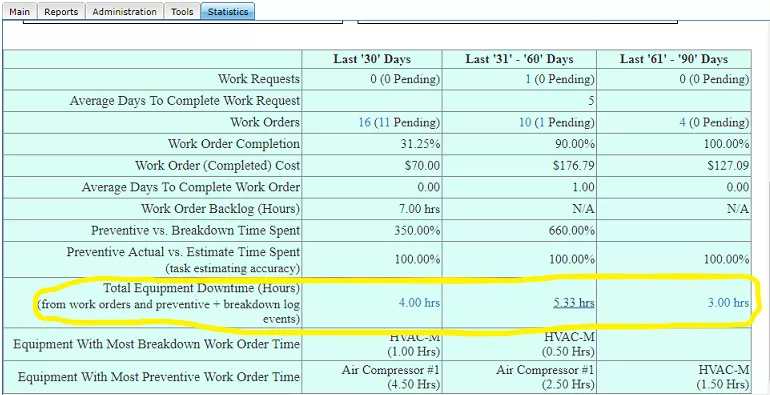

Below is an example from our FastMaint CMMS software showing equipment downtime over three prior periods. There was an small increase in the downtime in the last period which may or may not be significant. If this was expressed as an equipment availability percentage, the change would be so small that you would miss this.

Don’t look at me like that.

Work order time (duration) is not the same as equipment downtime

Why?

Because an equipment may fail at 1 pm and the work order to repair it is scheduled at 3 pm. The technician may do a temporary fix. This gets the machine running again while he waits for a part to come in stock. But the work order is still open.

The part comes in the next day. The tech completes the work order the next day at 11 am.

So the actual equipment downtime may only be from 1 pm to 4 pm and the next day from 10 am to 11 am when the work order is completed. This is about 4 hours of downtime. The actual time spent on the work order is two hours. This is from 3 pm to 4 pm on the first day and 10 am to 11 am the next day.

Make sure that reports from your CMMS software are not confusing the two!

You should log equipment events

Ideally your maintenance software should log when an equipment is unavailable. In addition also why it is unavailable.

Equipment could be unavailable for a variety of reasons, many of which may have nothing to do with the equipment. For example power problems, operators no available, assembly line issues, inspections and so on. This way you can separate the different reasons why an equipment is not available and collect actual statistics on downtime due to equipment problems.

Import equipment logs into the CMMS database

Many new equipment these days have a way to create log files of activity. You can import these into your maintenance software. This makes it easier to collect the information and not depend on operator or maintenance personnel reports for equipment downtime calculation.

Check the equipment manufacturer’s documentation to see if it is possible to have the equipment automatically export these logs (ideally as simple text files) to a common folder on your computer network. Now use your CMMS program to regularly import these files from the folder.

You may need to do some customization or changes to these export files since each equipment manufacturer may have their own export format. Your IT Department may be able to help you create procedures convert all these different formats to a single standard format that your CMMS software or other analysis software can use.

How Useful Is Equipment Downtime Tracking?

Being able to review equipment downtime information can help you identify potential causes. You may be able to address these causes and reduce future downtime incidents. For instance, if you see monthly downtime spiking repeatedly for some equipment you will want to investigate why. Reasons could be as varied as improperly trained operators, poor maintenance practices, equipment close to end of its useful life and so on.

Critical equipment when not available has effects felt organization wide. Production may be lost, quality may suffer and customers may experience delays getting products or services. In addition to reviewing the downtime data, you may wish to do some statistical analysis if it is critical equipment. Even if the maintenance software does not offer such statistical analysis tools, you may be able to export this data to third-party tools that can do statistical calculations (for example a Weibull Failure Analysis).

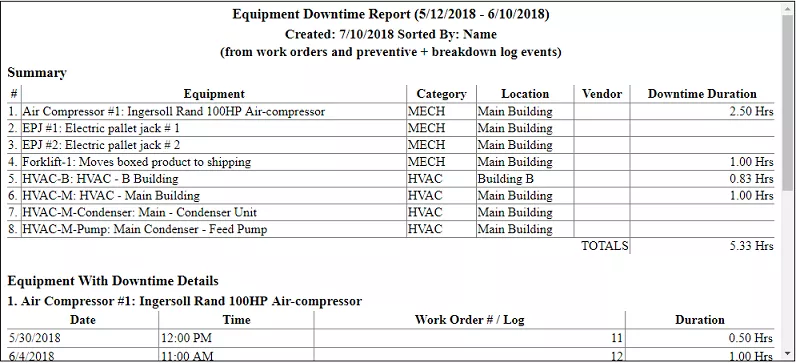

Below is a sample report from FastMaint CMMS showing a breakup of equipment downtime by equipment over a specific period. You can drill in to see the downtime cause – whether due to work on a work order or due to other causes from the log. Compare downtime by equipment over prior periods. Drill down to see what are the causes of any big changes.

Looking For Equipment Downtime Tracking Reports Like This?

Don’t have maintenance software that you can use to get such reports? Get a 30-day trial of FastMaint equipment maintenance software. You can import equipment, logs and more from comma delimited files. Use the reports and see if you find equipment problems that you can fix!

Free FastMaint CMMS TrialAdditional Reading

- Reducing Downtime with Legacy Equipment (IMPO Magazine)

- Maintenance Performance Evaluation and Downtime Analysis of Manufacturing Equipment in a Food Manufacturing Company (Journal of Engineering Research)

Essential Maintenance Metrics Every Planner Needs to Know

Get Free Guide